Your specialist for parallel keys …

Give us a call. We will be pleased to advise you.

fon: +49 (0)2391 91796–0

fax: +49 (0)2391 91796–30

GIB KEYS

GIB KEYS

- made to DIN 6887

- available from stock

- available in all materials with/without heat treatment

- custom dimensions possible

GIB KEYS

GIB KEYS

- made to DIN 6887

- available from stock

- available in all materials with/without heat treatment

- custom dimensions possible

MORE FACTS ON OUR GIB KEYS

| Width | w | 4 — 40 mm |

| Height | h | 4 — 22 mm |

| Length | l | 14 — 280 mm |

Customer dimensions available on agreement.

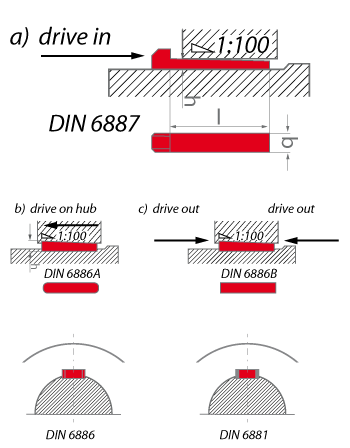

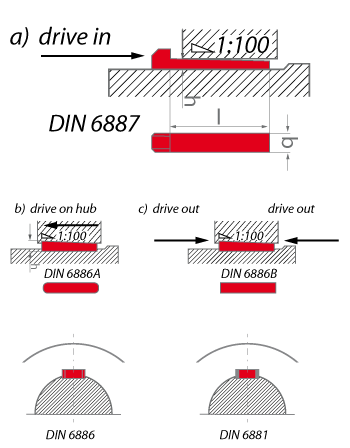

Wedge connections (see picture) are used today for the secure attachment of shafts and hubs of predominantly heavy disks, wheels and couplings in high-tonnage machines such as excavators and agricultural equipment. In other words, wedge connections are used when machinery is subject to severe operating conditions and mutual, impact torque. The forces are transmitted in these cases by friction locking and if this is not sufficient, the form-locking connection will come additionally into play. Wedge connections brace the shaft and hub against each other with wedges that have an incline of 1:100 and lateral clearance in the shaft and hub keyway. The wedge connection therefore occupies a position between a traction connection and a form-locking connection.

Wedge connections (see picture) are used today for the secure attachment of shafts and hubs of predominantly heavy disks, wheels and couplings in high-tonnage machines such as excavators and agricultural equipment. In other words, wedge connections are used when machinery is subject to severe operating conditions and mutual, impact torque. The forces are transmitted in these cases by friction locking and if this is not sufficient, the form-locking connection will come additionally into play. Wedge connections brace the shaft and hub against each other with wedges that have an incline of 1:100 and lateral clearance in the shaft and hub keyway. The wedge connection therefore occupies a position between a traction connection and a form-locking connection.

The advantages of this type of connection are the more uniform distribution of forces over the entire area, the reduced wear and tear as several lateral surfaces are simultaneously load-bearing, and the transmission of higher and variable torques.

Disadvantages: considerably more expensive, more marked weakening of shaft and hub, and high notch effect.

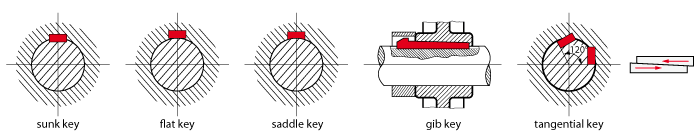

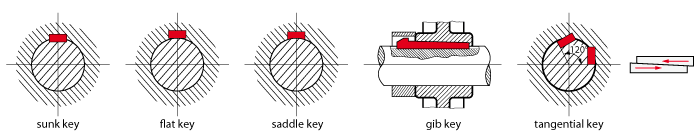

There are different types of wedge, which differ in shape and profile (see picture below). The different types of wedge are set by DIN 6881 (saddle keys), DIN6883 (flat keys), DIN 6886, DIN 6884 (flat gib keys), DIN 6889 (gib-head saddle keys).

Flat keys (DIN 6883 and 6884) have only very low form-locking but are characterised by a significantly lower notch effect than slot wedges.

Saddle keys (DIN 6881 and 6889) are rounded on the lower surface so that they fit directly on the shaft diameter (transmission of force therefore by friction locking).

Tangential keys (DIN 268 and 271) are suitable for high and variable torques. They are also used for split hubs (e.g. for flywheels). In this case, a pair of wedges are placed 120 degrees against each other tangentially on the shaft circumference..

Dimensions Available

Width w

4 — 40 mm

Height h

4 — 22 mm

Length l

14 — 280 mm

Customer dimensions available on agreement.

Wedge connections (see picture) are used today for the secure attachment of shafts and hubs of predominantly heavy disks, wheels and couplings in high-tonnage machines such as excavators and agricultural equipment. In other words, wedge connections are used when machinery is subject to severe operating conditions and mutual, impact torque. The forces are transmitted in these cases by friction locking and if this is not sufficient, the form-locking connection will come additionally into play. Wedge connections brace the shaft and hub against each other with wedges that have an incline of 1:100 and lateral clearance in the shaft and hub keyway. The wedge connection therefore occupies a position between a traction connection and a form-locking connection.

Wedge connections (see picture) are used today for the secure attachment of shafts and hubs of predominantly heavy disks, wheels and couplings in high-tonnage machines such as excavators and agricultural equipment. In other words, wedge connections are used when machinery is subject to severe operating conditions and mutual, impact torque. The forces are transmitted in these cases by friction locking and if this is not sufficient, the form-locking connection will come additionally into play. Wedge connections brace the shaft and hub against each other with wedges that have an incline of 1:100 and lateral clearance in the shaft and hub keyway. The wedge connection therefore occupies a position between a traction connection and a form-locking connection.

The advantages of this type of connection are the more uniform distribution of forces over the entire area, the reduced wear and tear as several lateral surfaces are simultaneously load-bearing, and the transmission of higher and variable torques.

Disadvantages: considerably more expensive, more marked weakening of shaft and hub, and high notch effect.

There are different types of wedge, which differ in shape and profile (see picture below). The different types of wedge are set by DIN 6881 (saddle keys), DIN6883 (flat keys), DIN 6886, DIN 6884 (flat gib keys), DIN 6889 (gib-head saddle keys).

Flat keys (DIN 6883 and 6884) have only very low form-locking but are characterised by a significantly lower notch effect than slot wedges.

Saddle keys (DIN 6881 and 6889) are rounded on the lower surface so that they fit directly on the shaft diameter (transmission of force therefore by friction locking).

Tangential keys (DIN 268 and 271) are suitable for high and variable torques. They are also used for split hubs (e.g. for flywheels). In this case, a pair of wedges are placed 120 degrees against each other tangentially on the shaft circumference..

Contact

Contact form

Contact details

Bannewerthstr. 18

58840 Plettenberg

Germany

Crummenerl GmbH (goods receiving / goods issue / truck access)

Bannewerthstr. 24c

58840 Plettenberg

Germany

Phone: +49 2391 91796–0

Fax: +49 2391 91796–30

Mail: info@crummenerl-gmbh.de

Web: www.crummenerl-gmbh.de

Contact details

Crummenerl GmbH (Office)

Bannewerthstr. 18

58840 Plettenberg

Germany

Crummenerl GmbH (goods receiving / goods issue / truck access)

Bannewerthstr. 24c

58840 Plettenberg

Germany

Phone: +49 2391 91796–0

Fax: +49 2391 91796–30

Mail: info@crummenerl-gmbh.de

Web: www.crummenerl-gmbh.de

Contact form